Pneumatic plugs with bypass (PPB)

Designed for bypassing of fluid or gas transported in the pipeline around the site of repair works.

The plug is designed in the form of a toroid-shape shell of rubberized fabric within a metal case with end-to-end port and tube for connection to the rubberized fabric hose used for the bypassing of the transported fluid or gas.

Plugs are used to keep the pipeline operating while repair works are being performed on a specific section of the pipeline or to check (test) the tightness of the pipeline and to eliminate clogging.

| Product designation | External diameter in the initial condition, mm | Casing length in the initial condition, mm | Weight, kg, not exceeding | Internal diameters of pipes blocked by a plug, mm | Air pressure in a plug, bar | Pressure of liquid (gas) in a pipeline, bar, not exceeding | Price, euro,w/o WAT |

|---|---|---|---|---|---|---|---|

| PPB 10/20 | 98 | 460 | 3,2 | 100-200 | 4 | 2,5 | 340 |

| PPB 18/30 | 170 | 590 | 10,0 | 180-300 | 4 | 2,5 | 429 |

| PPB 25/40 | 240 | 680 | 19,0 | 250-400 | 4 | 2,5 | 525 |

| PPB 38/60 | 378 | 850 | 36,0 | 380-600 | 4 | 2,5 | Contact the manufacturer |

Sealing plug overall view

1 – shell; 2– metal housing; 3 – branch pipe (DN and connection thread G are stated in the sealing plug service log); 4 – connection; 5 – hose; 6 – external valve; 7 – handle; 8 – nipple.

Sealing plug installation in the pipeline

1 – sealing plug; 3 – branch pipe; 6 – external valve; 9 – bypass hose; 10 – sealing plug hose extension; 11 – air supply unit; 12 – pressure monitoring unit; 13 – hose.

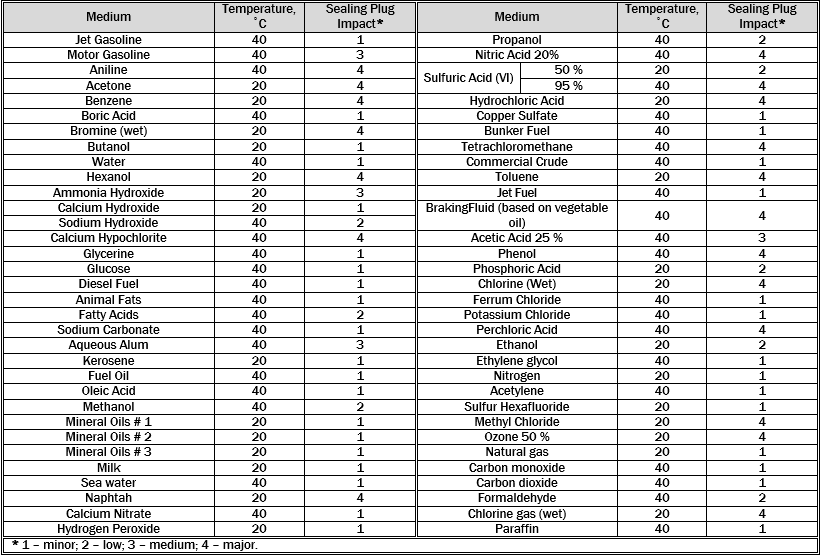

Chemical resistance