Pneumatic test plugs (PPT)

Pneumatic test plugs are designed to control sewage and other pipelines for tightness, clearing clogs and pressure testing, and can be used to bypass the fluid or gas transported through the pipeline around the repair area.

They represent a cylindrical rubber-fabric sheath, which has a through channel and a nozzle for connection to a rubber-fabric sleeve, through which the transported liquid is removed or water is supplied during washing or pressure testing.

Used in the repair and hydraulic tests for tightness of various piping systems. The products have a certificate of an approved sample, are accompanied by instructions and operation logs, a detailed description of the installation and dismantling process, safety requirements, instructions for storage and transportation, and manufacturer's guarantees.

| Product designation | External diameter in the initial condition, mm | Casing length in the initial condition, mm | Weight, kg, not exceeding | Internal diameters of pipes blocked by a plug, mm | Air pressure in a plug, bar | Pressure of liquid (gas) in a pipeline, bar, not exceeding | Price, euro,w/o WAT |

|---|---|---|---|---|---|---|---|

| PPT 38/60 | 365 | 750 | 22,0 | 380-600 | 4 | 1,5 | Contact the manufacturer |

| PPT 60/100 | 584 | 750 | 55,0 | 600-1000 | 4 | 1,5 | Contact the manufacturer |

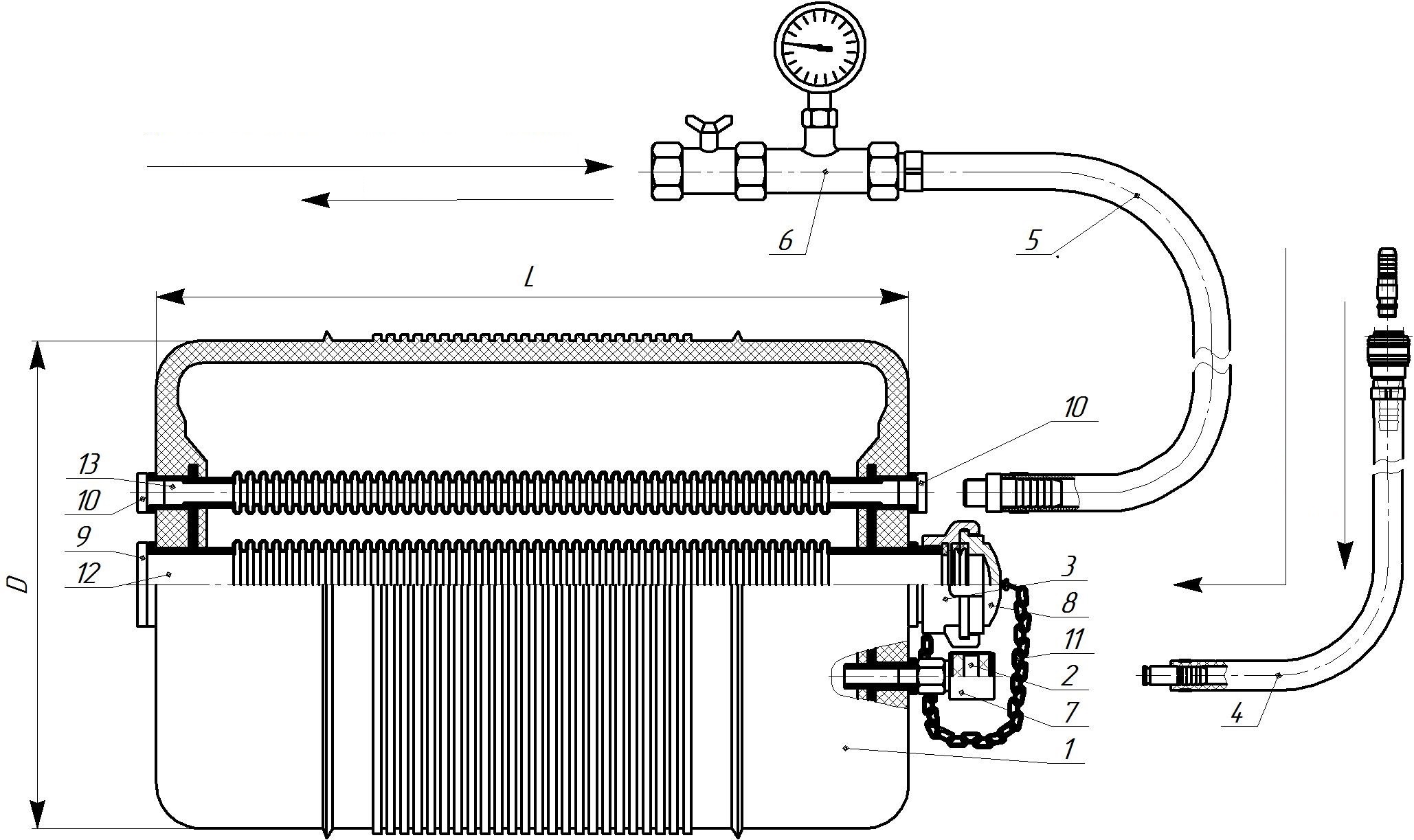

Sealing plug overall view

1 - PPT sealer shell; 2 - valve faucet g1 / 4-D12; 3 - coupling head GM-50-1,6 PM; 4 - PPT pneumatic line; 5 - hydraulic conduit; 6 - leak test unit; 7 - valve plug faucet; 8 - plug cap head GZ-50-1.6PM; 9 - plug of the water supply channel; 10 - control channel plug; 11 - chain; 12 - sleeve Dy-50; 13 - sleeve Dy-16.

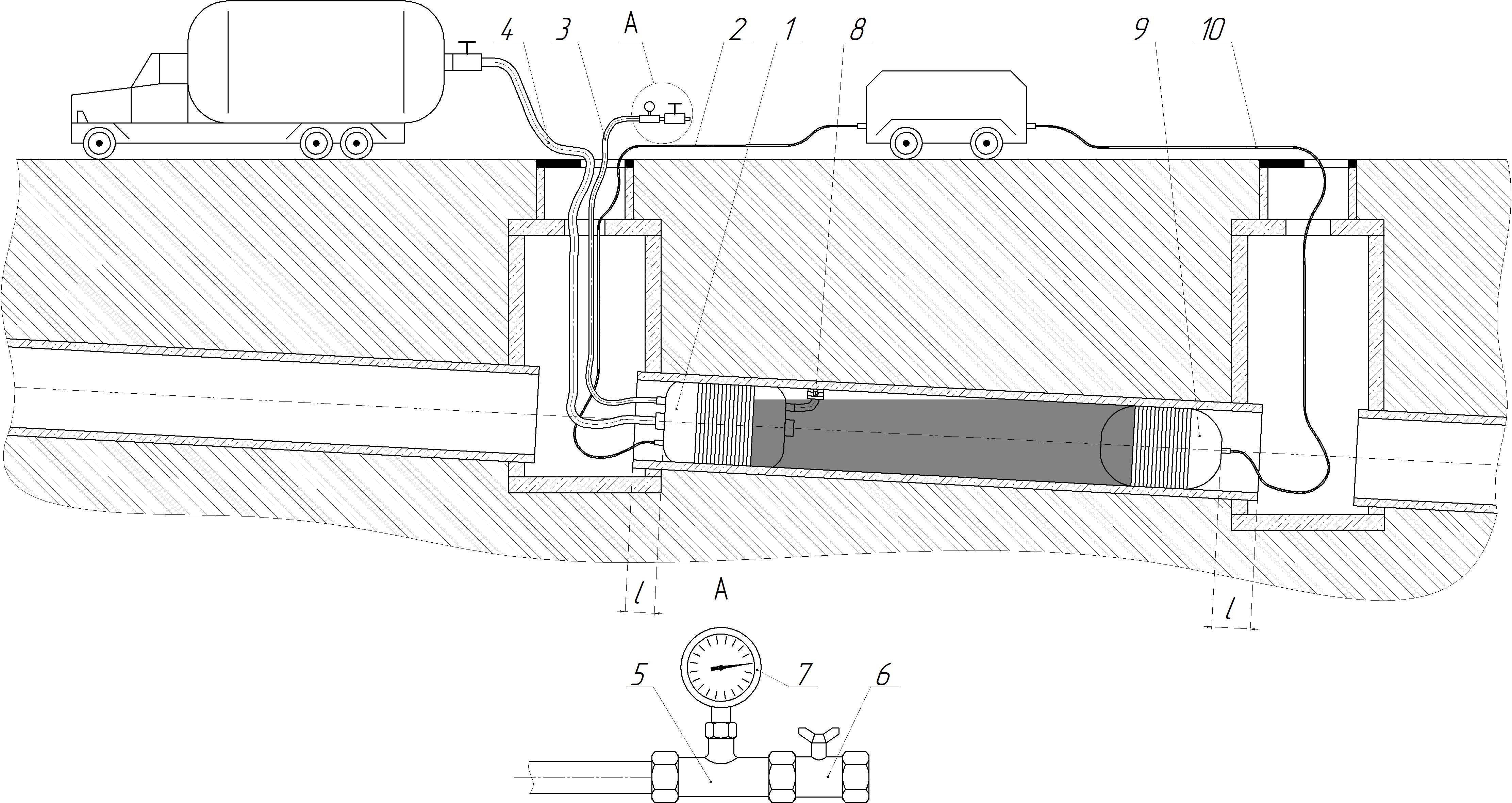

Sealing plug installation in the pipeline

1 - PPT plug. 2 - PPT pneumatic line. 3 - air hose (supply test pressure). 4 - water supply hose. 5 - tee. 6 - ball valve. 7 - manometer, 8 - float, 9 - PPT sealer, 10 - PPT air duct. l is the minimum distance from the pipe end before sealer.

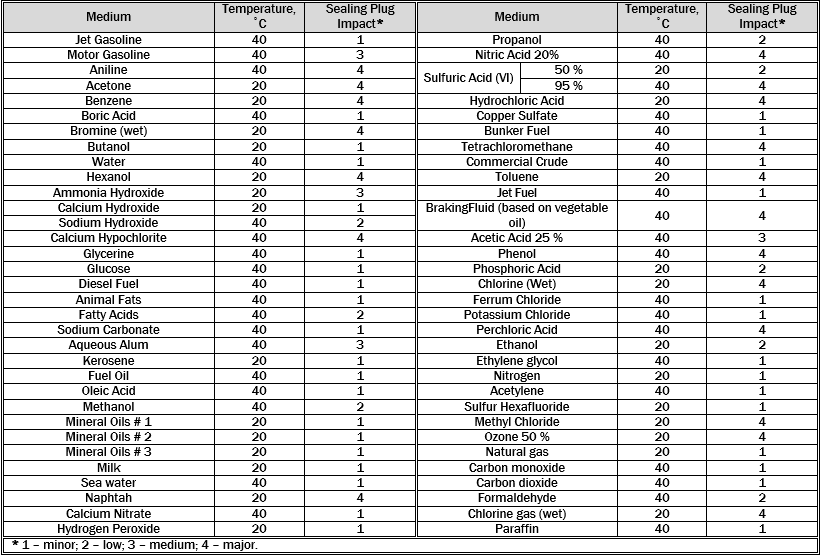

Chemical resistance